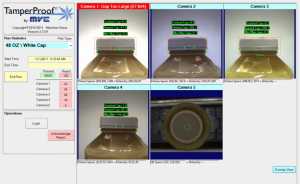

TamperProof®

Tamper Evident Cap Verification

Consumers take tamper bands for granted – they are trusted to work. But the high speeds and the nature of plastic packaging sometimes causes errors in the screw top application process. The TamperProof© System checks for any problems with the tamper-evident cap on screw-top containers. It will detect:

- High Closure

- Missing Closure

- Cocked Closure

- Broken Integrated Tamper-Evident Band

- Closure Color/Graphics Pattern

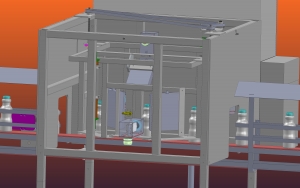

The TamperProof© system uses four side cameras to verify that the tamper-evident band is:

- Properly installed

- Is not skewed

- Is properly torqued.

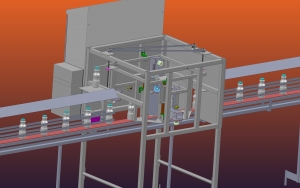

In cases where multiple caps are used the system will verify that the correct cap is on the container. It performs all verification and inspection through non-contact means, requiring no special handling of the product and no stopping of the product flow on the conveyor.

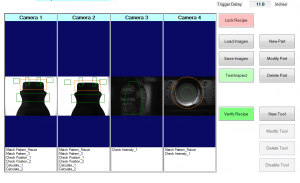

- User-friendly GUI with an easy-to-use interface to configure and load the container inspection recipes, minimizing changeover time

- Store and manage hundreds of SKU inspection recipes

- Secure access in the form of multiple log-ins and passwords

- Color touch-screen monitor

- Maintain production speeds up to 900 per minute

- Non-contact inspection and no slowing of the production line

- No special container handling needed, other than to ensure that the cap areas are appropriately spaced on the conveyor as they pass through the TamperProof system

- Inspection tools include:

- Pattern-finding to match flavor graphics, product graphics, logos, or other features

- 1D and 2D barcode reading to identify the cap

- Tools to measure cap placement and skew

- Any number of vision tools can be used for inspection

- Event logging to create an audit trail for log-ins, log-outs, container SKU changes, and recipe configuration changes

- Reporting of session (run) statistics at the end of a product run

- Data analytics support

- Biometric (fingerprint) security access

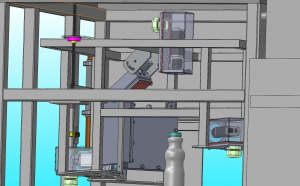

- Color or monochrome camera for lid or cap inspection

- Wash-down IP67 construction with air conditioner for electronics

- Fool-proof height adjustment mechanism for the top camera

- Singulator to ensure proper container spacing to provide 360 degree inspection of the closures

- Centering device to guide the container through the center of the inspection point

- Multiple rejecter options

- Air blow-off

- Pneumatic “punch”

- Guide to another conveyor or reject table for re-work

- PLC for reject monitoring and line control