CircumSpect®

360° Graphical Inspection for Cylindrical Containers

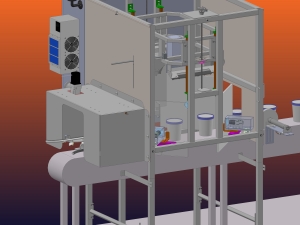

CircumSpect is perfect for applications that require a graphical inspection of a round or cylindrical container. Cylindrical containers often pose a challenge for inspection systems because it is usually impossible to control where the label is facing on a production line. Circumspect is the solution for clients in the food & beverage industry who want to have an end-of-process inspection of a round product.

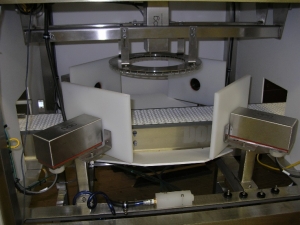

The CircumSpect® system creates a 360-degree view of the containers using 4 side-mounted cameras. The software algorithm combines the four images into one continuous “un-wrap” image of the entire side circumference. The un-wrapped image can then be processed by a wide range of standard machine vision tools.

The vision tools available for use include:

- Pattern matching

- Pattern inspection

- Gauging

- Brightness inspection

- Color matching

- Linear barcode reading

- 2D barcode reading

- Optical character verification (OCV) of well-printed codes

- Multiple vision tools may be applied to each image and inspection recipe

A strong recipe manager is standard on the CircumSpect® system. This allows users to quickly switch between pre-configured recipes and transfer recipes from one system to another.

- User-friendly GUI to configure and load the label/container inspection recipes, minimizing changeover time

- Store and manage hundreds of SKU inspection recipes

- Secure access in the form of multiple log-ins and passwords

- Color touch-screen monitor

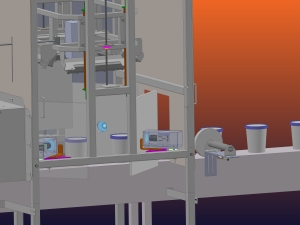

- Maintain production speeds up to 900 per minute

- Very low false reject rates

- Non-contact inspection and no slowing of the production line

- No special container handling needed, other than to ensure that the containers are appropriately spaced on the conveyor as they pass through the CircumSpect system

- Inspection tools include:

- Pattern-finding to match flavor graphics, product graphics, logos, or other features

- 1D and 2D barcode reading to identify the label or container

- Tools to measure label placement and skew

- Any number of vision tools can be used for inspection

- Event logging to create an audit trail for log-ins, log-outs, container SKU changes, and recipe configuration changes

- Reporting of session (run) statistics at the end of a product run

- Data analytics support

- Fully wash-down NEMA-4X configuration

- 5th camera options for lid presence and verification or code verification

- Fool-proof height adjustment mechanism for the top camera

- Singulator to guarantee correct product spacing

- Centering Device

- Rejecter